CBS alumni return in mission to change the world – one serving at a time

The aim of Kleen hub is to replace single-use packaging with reusable sustainable products and the start up works together with Jespers Torvekøkken. (Photo by Mette Koors)

Three former students have combined their activism with the wonder of stainless steel and turned it into a thriving business, a finalist spot in a global competition and opened a new market. Now they have returned to CBS for a partnership with Jespers Torvekøkken.

For a few weeks, a streamlined stainless-steel cup has been an option for coffee drinkers in the canteen at the Solbjerg Plads Campus. It was introduced by the startup Kleen hub, which provides reusable cups and meal boxes for the food industry, and the concept could not be more homegrown.

In 2019, three students spent hours in a study room above the canteen at Solbjerg Plads formulating a business concept. Now that idea has grown into a business, Kleen hub, and this month the now former students returned to CBS with their project, as partners with Jespers Torvekøkken.

Simone Favorita, Guiseppe Lanzafame and Robert Dichtl co-founders of the start up. (Photo by Kleen hub)

“It is an honor for us to come back to our university and our roots as entrepreneurs. We started this company to make a change and to fundamentally empower people, institutions and businesses to choose a truly sustainable choice that fights the single-use culture,” says Simone Favorito, co-founder of Kleen hub.

Denmark’s green paradox

Since July of 2021, the three founders, Guiseppe Lanzafame, Robert Dichtl and Simone Favorito have worked full time on the startup, and Kleen hub now has 110 partners among mostly restaurants, cafés and takeaway places in Copenhagen. But it is also partnering up with universities such as KU, DTU and ITU, a few hospitals and offices. Its strategy for 2022 is to expand into hospitals, catering and corporate offices, and more universities.

For the moment, Kleen hub is based and operating only in Copenhagen and Aarhus, but the start-up has an international team who are hungry to make a difference.

“Our goal is, of course, to make a strong and viable solution, but even though we are focusing on our core for now and making it here in Copenhagen, we want to expand. Single-use packaging is a worldwide problem, and we have global ambitions to provide the solution,” says Robert Dichtl.

They found that starting a business in Denmark was an easy choice but also a surprising place to find a gap in the market.

“Denmark is one of the greenest countries in the world with a focus on sustainability. There’s already a return system in place, and everyone bikes everywhere. On top of that, there is a good environment for start-ups. So, there’s already a behavior pattern in place and a helpful environment where our business model could easy find a receptive audience,” says Simone Favorito and continues:

“However, Denmark doesn’t have any green solutions for food packaging. That makes no sense, as it is a huge and underestimated problem. It is time for a solution, and we are ready to provide it.”

Starting a movement

The concept for Kleen hub came to life during a takeaway dinner in the summer of 2019.

“We had a lot of different Thai dishes and there was a huge amount of plastic waste. That made us consider what could be done to reduce it,” says Robert Dichtl.

Over the next few weeks, the dilemma was still occupying them, and they continued to brainstorm alternatives to the vast amount of single-use packaging in our society. By chance, Guiseppe Lanzafame came across National Geographic’s Ocean Plastic Innovation Challenge and they decided to enter the competition, kicking off their life as entrepreneurs.

“We actually went to CBS on a Sunday for 13 hours. We locked ourselves in one of the meeting rooms in Solbjerg Plads above the canteen to work on the idea and the pitch for the competition,” says Robert Dichtl.

Kleen hub’s design entry was chosen as one of ten finalists out of 400 applicants from all over the world and they won $5,000. In November 2019, they were flown to Washington DC to pitch in front of a jury at National Geographic’s headquarters and had the opportunity to win the $100,000 first prize plus additional investment.

“It was amazing, and we learned so much. We met a lot of cool start-ups there who were also working on reusable packaging. We didn’t win anything, but we came back with a lot of insight, and a lot of feedback from the high-profile judges,” Robert Dichtl.

(Super)cup of steel

The insight and feedback made them decide to change focus to reusable packaging instead of recycling or redesigning single-use products into greener alternatives.

“We started out aiming to make products from reusable bamboo, but discovered that bamboo products are combined with plastic that can be released into the food or drinks if it is hotter than 90 degrees. So, on top of not being sustainable, we found out this would have been potentially harmful to consumers, so we changed our material choice,” says Simone Favorito.

In general, they realized that a lot of products sold as sustainable were misleading consumers.

“If something is green, bamboo or even just brown, people think it is sustainable, but they are not. Claiming a product is biodegradable is most often greenwashing. So along with pitching our concept, we have to educate our partners that single-use products, no matter the material, are problematic. You take resources, you chop down trees, you produce something and then you can’t really recycle it. That’s really a big problem,” says Robert Dichtl.

Instead, they have decided to make their products from stainless steel due to its overall quality.

“Sure, it takes more uses to break even with stainless-steel products because the emissions are higher, but they are much more durable, don’t really stain or degrade, and you can always recycle them. From both a sustainability aspect and as a business model, it makes sense to buy something that lasts for a really long time,” says Robert Dichtl, adding:

“To be sustainable, our small cup has to be used 27 times before it breaks even. For the bigger cups, it’s 33 times. Then you can go up to 1,000 uses or in more basic terms, stainless steel is indestructible. With a plastic cup, it’s probably around 10-20 uses before they break even, but they also break down after about 250 uses. So, the more a product is in circulation, the better it is for the environment.”

By using stainless steel, they want to challenge the idea that everything has to look new and fresh all the time, instead emphasizing that something reused is something shared, scratches and patina don’t mean it doesn’t work anymore, as long as the design is good.

“A good design accelerates change. It makes it easier for people to switch to a new solution. Good design also helps people understand the higher value of our reusable products,” says Simone Favorito.

And according to the three founders, a big change is needed to combat the destructive habit of using single-use packaging.

“Where we are right now in terms of becoming sustainable is that we need to realize recycling is part of the problem. Of course, recycling is good, and we need to continue doing it, but it is far from enough to keep up with our single-use culture. It isn’t effective enough, so we must focus more on changing consumer habits worldwide away from the single-use culture,” says Robert Dichtl.

A closed loop

Before the Covid pandemic, the plan was for Kleen hub’s product to remain in a closed loop like festivals and big events, to ensure it was returned. But as the world changed, so did the business model. Kleen hub changed its focus from festivals to takeaway places, as well as store restaurants and cafés, and has launched products such as thermo cups and meal boxes to meet customer needs.

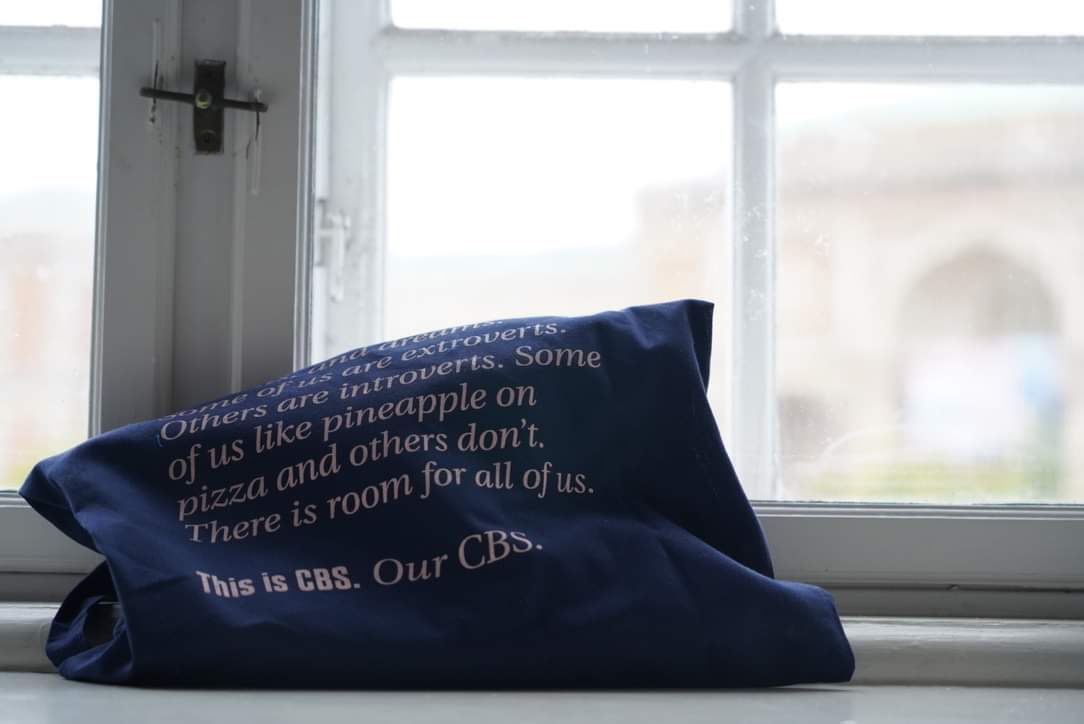

(Photo by Signe Mereta Lauesen)

“We switched very quickly, that is the advantage of being a startup, and we are a team founded on speed and execution. At that time, it was a minor change to our business model, but it made sense,” says Simone Favorito.

Kleen hub has no plans to sell its product directly to consumers because it believes promoting circulation is better for the environment.

“We could have made it much easier by just putting our product on Amazon, but we aim to reduce single-use packaging, and in order to do that, products must remain in circulation,” says Robert Dichtl.

They find that making quick but calculated decisions has helped Kleen hub get a good start as a business.

“Execution and ‘not perfection’ are key. If you wait to launch until you have a perfect product, you would have launched too late. There is no such thing as a perfect product. Build a minimum viable product, test it, learn from it, implement those learnings and repeat! Execute, test and learn – those are the keys to our success and we keep them in mind when getting down to work. We are not scared of testing things,” says Simone Favorito.

Comments