They make their own chewing gum

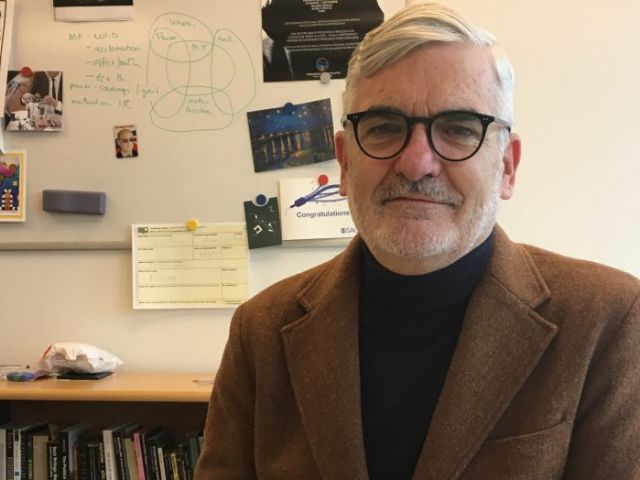

The founders of True Gum (From left to right: Jacob Motzfeldt, Peter Regnersgaard, Zabrina Ziegler, Morten Ebdrup)

What started off as a project being done for fun in the kitchen, turned into a growing business. Chewing gum has been a blight for cities all across the world, but now it does not have to be. Three CBS alumni came up with an organic, decomposable solution.

Chew it, spit it out, and then leave it on the ground. That is what a majority of people do when they chew gum. But what they might not know is that the generic gum they are chewing is made from plastic and it will not simply disappear by itself.

Morten Ebdrup and Peter Regnersgaard, CBS alumni and cofounders of True Gum, found themselves wondering exactly what chewing gum was made out of. Their curiosity was set off by the stark contrast between the wholesome organic dinner that they just finished eating and the multicolored, cherry flavored chewing gum that they ate after.

“We had no idea what was inside. It made us wonder why is it that chewing gum stays on the street for years and years after you chewed it. All the other food that we consume decomposes when it’s left to lie in nature,” says Morten Ebdrup.

Upon inspecting the ingredients of the package, the two of them noticed that one of the main ingredients in chewing gum was ‘gum base’. Well, that did not exactly answer their question, so they did what any millennial would do in this situation, they turned to Google.

What they discovered was shocking. Gum base consists of approximately 80 components, some of which is the same that is used in plastic bottles, glue, and even rubber tires. In fact, the owners of the patent for gum base is Good Year, a tire manufacturing company.

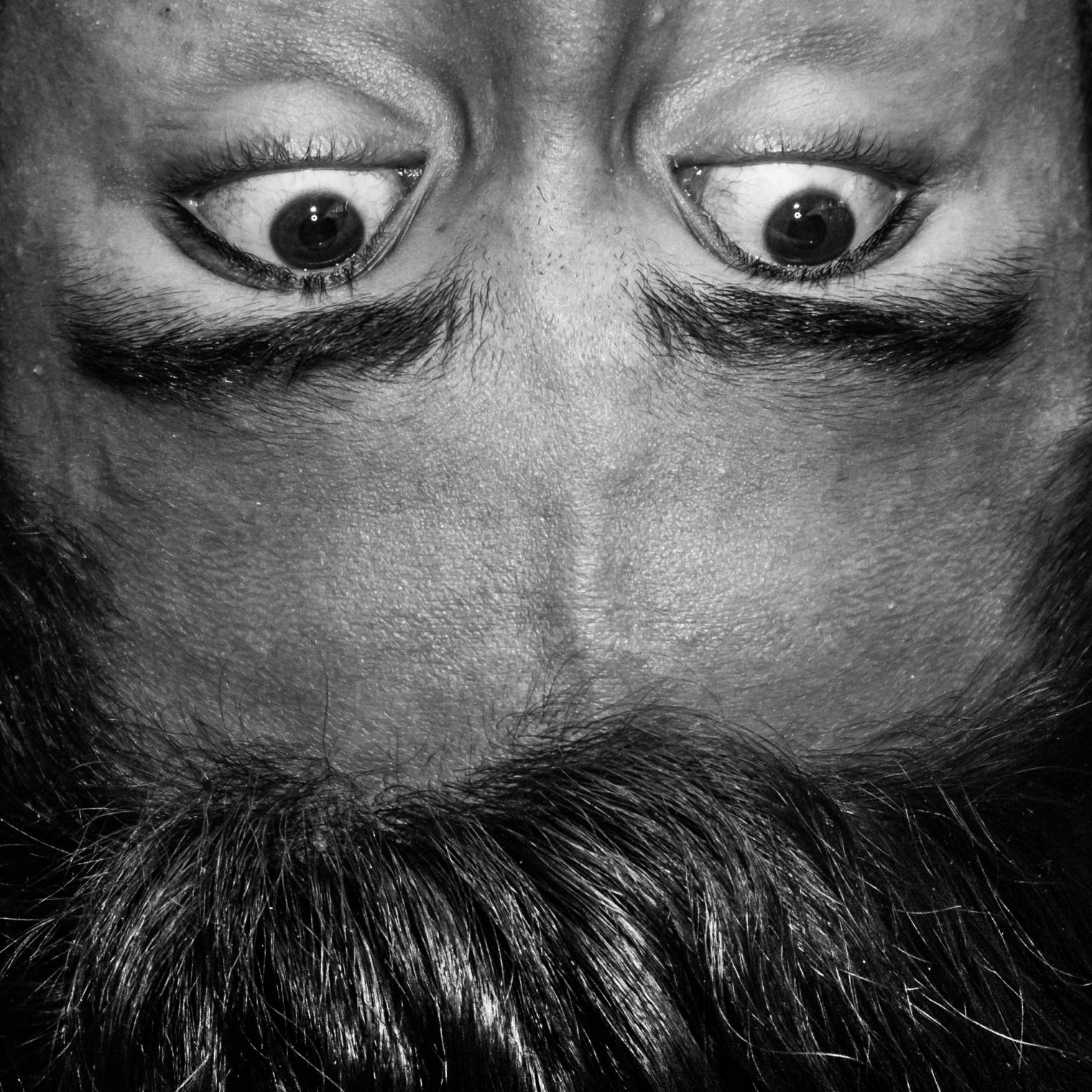

Zabrina Ziegler and Peter Regnersgaard checking the consistency of the gum. (Photo by: Julia Corradi)

It was not too long after that until they decided to try making organic, biodegradable chewing gum with real ingredients and no artificial flavoring.

At first, they started experimenting with four to five ingredients including licorice and ginger. The main chewable ingredient in the gum is made from the sap of the gum tree, which is found in Central America.

“We started investigating how they made chewing gum back in the days. We found out that in the old Inca civilization they were also chewing gum and they were using the sap from a tree that grows in the Central American jungle. We’re using the same naturally occurring gum from that tree. when it ends up back in nature, or on the street it will decompose like an apple would.”

Even though gum always belongs in the trash, the biodegradable gum loses its stickiness and turns into decomposed powder after approximately six weeks.

From the kitchen to Lokomotivværkstedet

The two co-founders began by making small experiments in Morten Ebdrup’s shared flat. Every afternoon, for a year, the two of them would try to make chewing gum the old-fashioned way. They found the process to be a lot harder than expected, but after 472 trials they finally had a prototype in February 2017.

The time came for the team to expand, says Morten Ebdrup.

“We needed someone who can take this product further, and help us ensure that the quality is up to par. That’s how we found Zabrina, who’s now in charge of developing the product.”

With the team complete, Morten Ebdrup, Peter Regnersgaard, Zabrina Ziegler, and Jacob Motzfeldt (A friend from the IB program at CBS) began working full time on the project.

“We had to look for a place to be because at this time we were still in the apartment. We had two other roommates, and when they left to go to work in the morning, we took over the apartment. We transformed the apartment into an office and production facility for testing in our own kitchen.”

This is the building where all of the magic happens. (Photo by: Julia Corradi)

After several networking events, the True Gum team connected with the owners of Reform, a company dealing in customizable kitchens, who offered to invest funds into True Gum and offered them a place to produce.

“They really liked the idea and we just hit it off on a personal level. They gave us a little bit of money, and together with what we had, it was enough to buy the first machines. This allowed us to take this to a larger scale,” says Morten Ebdrup.

From Museums to Roskilde

In December 2017, True Gum launched their website and opened their doors for online orders. Since then, they are selling their gum in over 200 locations including 7-Elevens around Denmark, organic food stores, Arken, and Louisiana.

The future is looking bright for True Gum, as they will be expanding to new stores and markets. By the time September rears its head in, True Gum is expecting to seal a deal with Irma and will have already been to Roskilde Festival handing out gum to the festival goers.

“We’ll be biking around Roskilde Festival without chewing gum because Roskilde had a big problem with chewing gum laying on the ground when the festival was over.”

True Gum can be found in 7Elevens, Arken, Louisiana, and soon to be in Irma as well. (Photo by: Julia Corradi)

The founders of True gum have also been in contact with influential entrepreneurs and tv figures who will be helping the company expand internationally to other Scandinavian countries and Germany.

“One of the key reasons why we’re here today is that people have been very friendly and spent time helping us. Even some of the people that you see on tv, the big shots, they take time out of their calendar to lend us a hand. We’ve been very fortunate to have people like that and it’s greatly appreciated,” says Morten Ebdrup.

Comments